Heating / Temperature Management

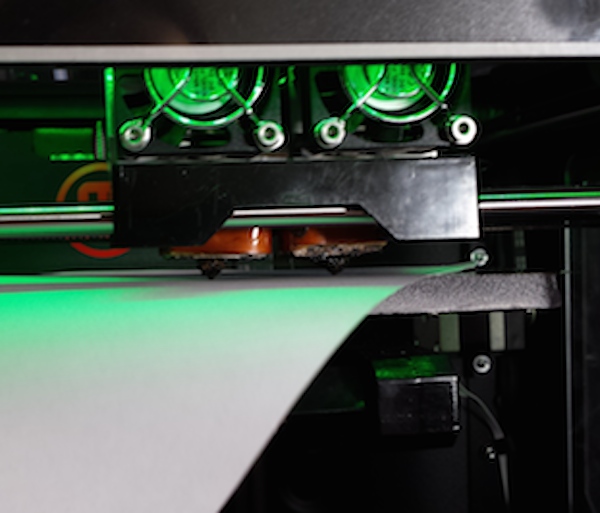

Insulate the Hot End

Insulating the hot end helps in two very important ways. It reduces extruder jams by preventing your material from becoming gummy near the gnurled extruder. This also improves accuracy of the extrusion resulting in much better looking parts, specifically when the software calls for a filament "retract" it actually retracts instead of just stretching. The insulation also makes the heater block "hold" in more heat so the software can keep the nozzle at a more accurate temperature.

Filament

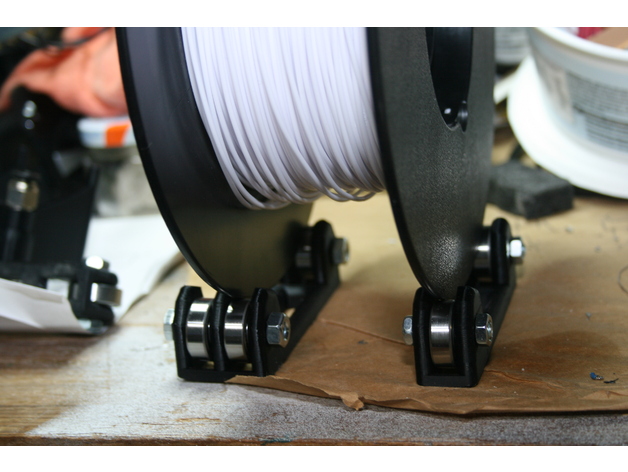

Friction-less Filament Spooler

I found when I minimized my filament friction, the extruder has less chance of slipping and I haven't had a jam since. The print quality increased so much that the prints are now reflective!

Print Basics

Basics: Blue Tape the Print Bed / Level the Build Plate / Lube the Nozzle

The basics will get you pretty far with these fickle 3D printers. Get the wide blue tape and cover the whole bed, then use a putty knife to pop your builds off the plate. I prefer to level my build plate using something thinner than a business card, I found that a business card was too thick and my first layer to peel up. If you're having issues with the build peeling up, try printing on a raft. I found that heating the nozzle up to 190-200 then pulling out the old filament, you kinda "grab" a bunch of the impurities that have been accumulating in there. I cut the tip off and then dip the fresh tip of filament in olive oil/canola oil/gun oil and load it back into the extruder. The whole process only takes a couple minutes and has really reduced my number of nozzle jams.