Ever wondered how an SLA printer works?

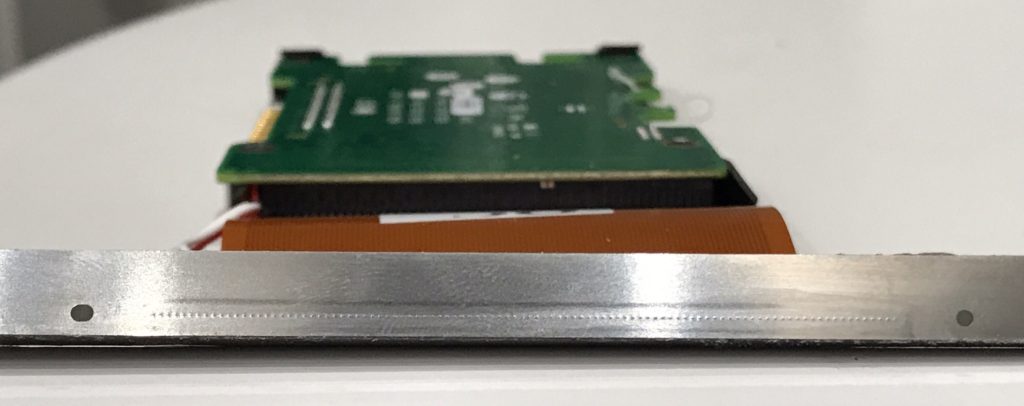

Well here's the simple version. You load in a cartridge of special resin which cures when exposed to UV light. The printer I use has eight "heads" (one shown below).

The prototyping machine prints your model, slice by slice. Our printer uses two xenon lamps to cure the resin within seconds of exiting the head.

Basic printers like ours utilizes two types of resin; model material and support material. Newer printers can utilize a variety of materials at once allowing a multitude of colors and material properties to be incorporated into one print.

The major leap in SLA printing technology hasn't actually been the in the printers, in fact SLA printers have not changed much over the last 15 years. The large leaps have been in the available materials for printing such as dissolvable support material and model material that simulates rubber, polypropylene or ABS to name a few.

Similar to FDM printers, SLA printers have their quirks and hurdles. The main one is keeping the nozzles clear. In total there are eight heads so you can imagine how important the routine cleanings are. Other than that, they are pretty straight forward.

The main benefit SLA printers have compared to FDM printers is their accuracy level vs. time and consistency. In laymans terms, the FDM printers are real quick and dirty and the SLA printers are more involved but the results are better. Kind of like back purged tig welds vs mig welds... they both have their ideal applications.

And a real life example: If I were to 3D print two puzzle pieces for a conceptual demonstration, I'd choose an FDM printer. If I were printing an entire puzzle that had to fit together nicely then I'd use the SLA.

So there you have my quick take on SLA printers!

Joe