Who am I?

Let me qualify myself before we get into anything. I'm a total nerd and car guy, I've rebuilt carburetors and distributors, I've built megasquirt's and tuned them and I've tuned my Subaru with the factory computer. They are all vastly different ways of doing almost the same thing, with different priority levels. For this article I want to talk about tuning the factory Subaru ECU. Lets start with an admittance. The car ran best when it drove off the dealer lot. So lets get back to that and think about why for a second. The OEM has vast resources and characterizes the computer to the engine. They use huge flow benches and have entire facilities dedicated to engine characterization, so you can bet your life savings that the MAF curve and target AFR are there for a reason. Before the engine ever sits inside a car it has been graced by a group of god-like individuals who know the engine better than you know your own di- I mean hands.. yeah, hands. They have a lot of requirements to mee which is part of the reason things don't always make sense to us car buffs. One example of this is the SAE horsepower rating. Lets say your vehicle has a factory rating of 280 hp and 250 lb-ft of torque at 4300 RPM. To earn this rating, the engine must provide 250 ft-lb of torque at 4300 RPM for 60 seconds. Consider this, and the amount of resources the OE put into designing your engine controller when you decide to make a change.

Now that we got that out of the way, how can we make more powahhh?

Run More Boost

How Much Boost Can I Run?

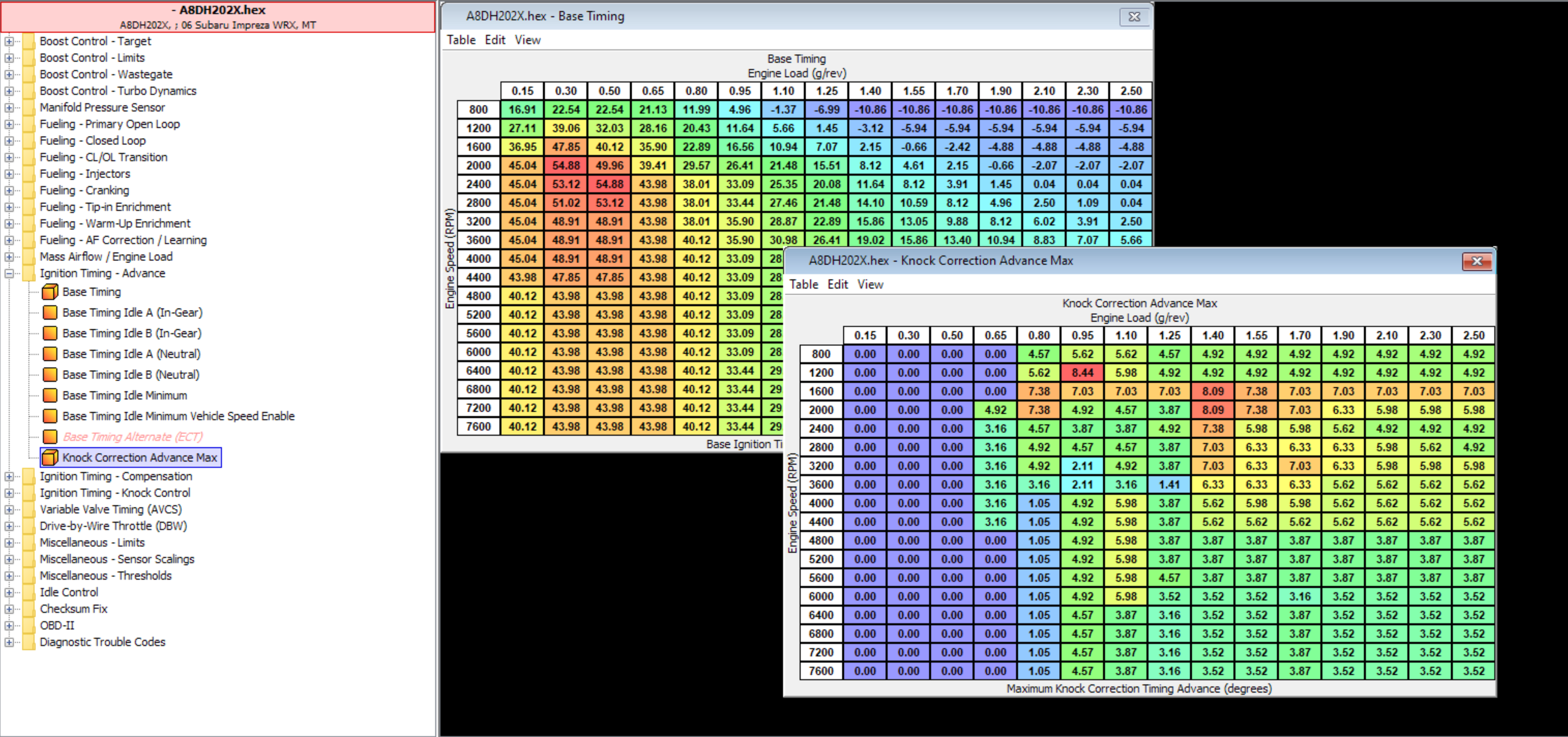

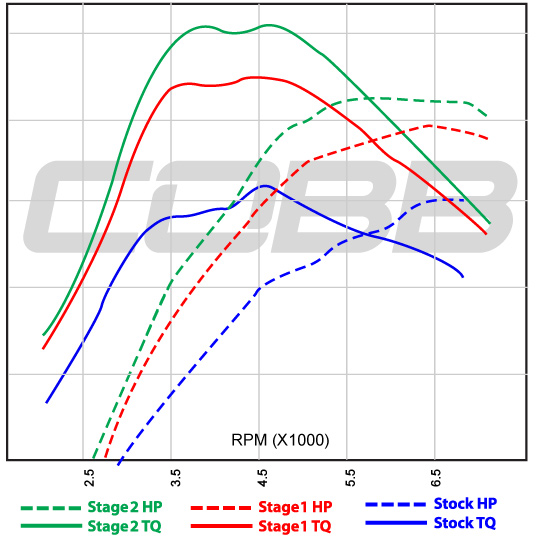

Not all of it, let me tell you. Oem's are obsessed with responsiveness and torque so for us tuners any factory turbo vehicle is going to come with a turbo that is optimized for peak torque at like 3500 RPM. Well guess what, it's a restriction we can't afford at 7000 RPM. How do we know that? We do math and parse datalogs. Before doing anything, you must first have a specific goal because your time and money will be wasted otherwise. My goal was to make more torque over 4500 RPM. Take a look at the factory torque curve from Cobb tuning. Notice where it falls off.

If you are Subaru, you don't want a giant torque spike, you want a smooth torque curve that doesn't fall off, and that's exactly what they gave us. The kicker is that the stock EJ255 comes with the same TD04 that the EJ205 came with...a small turbo for the torque curve most desire. I'm going to ramble for a second: A turbocharger essentially raises and lowers the dynamic compression of the engine. You can accomplish the same increase by changing pistons to "high compression" but the similarities end there. The turbo is "powered" by the turbine wheel when exhaust gas is forced through it. Intake gas enters, it combusts and expands driving the piston down then exits. About 3x the volume of exhaust is created vs intake gas. This is useful to keep in mind when sizing turbos. A turbine wheel that is too small will "plug" the exhaust and the engine cannot get all the exhaust gas out. The hot exhaust gas remains backed up in the cylinders and prevents some of the intake charge from entering. This is what causes the torque curve to fall so rapidly after a certain point. So lets make the turbine wheel huge..Too large of a turbine wheel and your turbocharger will never "spool". So there is a turbine wheel size that balances exhaust flow so you are not "plugging the exhaust" and still spins the compressor wheel to make your desired power. The blade and wheel size and design of both the turbine and compressor is what Garrett and Holset specialize in. Generally, compressor wheel size is based on the turbine wheel and anticipated flow rate. The main thin here is that the higher boost you run, the higher your dynamic compression is. The higher boost you run, the more the charge temp increases. The more the temp increases, the less resistance to detonation you have. You can combat this with a larger intercooler but you can't fix a turbine wheel that is too small. So take that TD04 and throw it out the window.

BACK ON TRACK

The V39=V48 are much better suited to the 2.5L engine for low boost levels. If you wish to make mroe than 280 wheel HP you need a real turbocharger, sized for the torque curve you're after.

Lets Raise It Already!!!

With CA91 gas, I'd really only raise the TD04 up to 15 psi. I'd recommend an intercooler upgrade to the STI as well. ~250hp

VF48, I'd run 18 psi tapering to 14. Tapering because it's so far out of it's efficiency range that you can make more power with 14 psi and decent timing vs 18psi and severely retarded timing. ~300hP

20G I'd go 18psi and run more aggressive timing. ~350hp

GT3076R I'd stick to 16-18psi and run aggressive timing. ~400hp